Scientists at Rice University have come up with a promising solution, brushing the electrode surface with a fine powder to ensure the electrode’s survival.

In lithium metal batteries, graphite is replaced by pure metal lithium as the anode. The material offers a very high energy density, allowing batteries to charge faster and provide up to 10 times the capacity, but making them work reliably for long periods of time has so far proved difficult.

As the battery cycles, dendrites start to form on the anode and can cause the battery to short out, malfunction or catch fire. We’ve seen many interesting potential solutions to the dendrite problem, and Rice University scientists have been responsible for more than a few, with nanotube films, tape and laser treatments just a few recent examples.

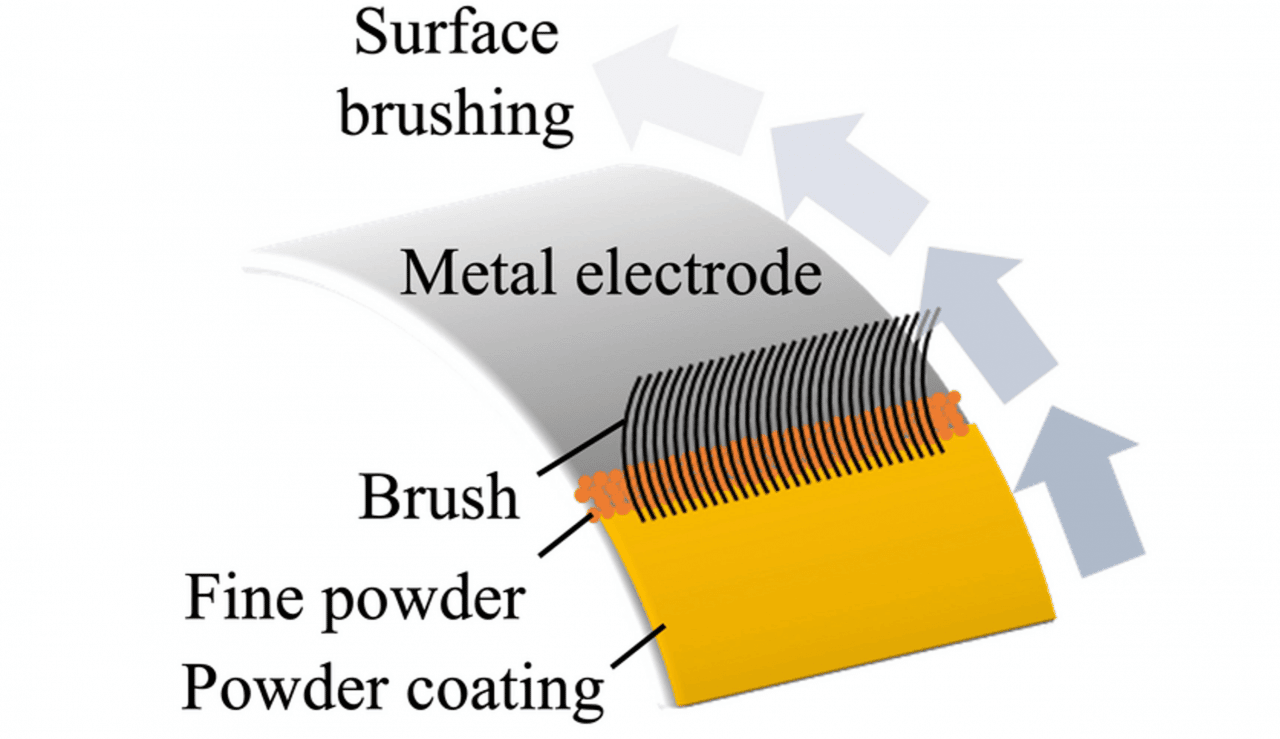

In the latest work by battery scientists led by chemist James Tour, they have attempted to address this problem with a novel tooth-brushing treatment. The technique starts with brushing the anode to create a textured surface, and then brushing with a powder made from phosphorous and sulfur. This causes the powder to react with the lithium metal anode, forming a fine protective film that changes its surface energy.

Above: Schematic depicting the protective powder brushing technique developed at Rice University.

“This provides a metal-composite surface that prevents the loss of lithium metal from the anode, which is a common problem with lithium metal batteries,” said James Tour. Metal lithium batteries have far greater capacities than traditional lithium ion batteries, but metal lithium tends to It is difficult to recharge repeatedly.

The film has the effect of conditioning the anode surface, promoting more uniform behavior during cycling, thereby increasing the life of the battery. It ran 340 charge cycles in the test batteries and found that they retained 70 percent more capacity than existing batteries. The film also performed well on another key metric of battery degradation, maintaining ultra-low polarization for more than 4,000 hours, about 8 times longer than the anode without the film.

James Tour said: “This will simplify the manufacture of high-capacity batteries while greatly improving them. Grinding these powdered solids into lithium metal anodes can significantly reduce dendrite formation, thereby reducing battery short-circuits and speeding up material consumption. .”

The research was published in the journal Advanced Materials.

GIPHY App Key not set. Please check settings