Unlike sensors in other wearable devices, this flexible sensor retains the inherent properties of fabrics, such as abrasion resistance, breathability, and the ability to touch the skin for a better tactile feel.

1. Based on cotton to manufacture flexible sensors, 1 yuan produces 1 meter, so that manufacturing and cost are not a problem

This sensor is made of a conductive thread called PECOTEX, and PECOTEX was developed by Imperial College London based on cotton. The cost of producing 1 meter of this PECOTEX wire can be as low as $0.15 (equivalent to 1.07 RMB).

PECOTEX can seamlessly weave more than a dozen sensors into clothing, and when designing it, researchers have taken care to make PECOTEX compatible with industry-standard computerized looms to facilitate subsequent textile manufacturing.

Fahad Alshabouna, lead author of the PECOTEX conductive thread paper and PhD candidate in the Department of Bioengineering at Imperial College London, said: “As a flexible medium, clothing fabrics could enable a wider range of applications for the sensors we developed, and we have Solving most of the problems in production makes this sensor more convenient to produce, which also means that when the scale of manufacturing is scaled up, the market may usher in a new generation of clothing-based wearable devices.”

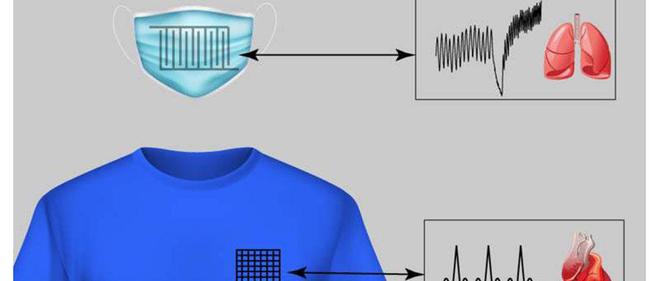

The team’s researchers woven sensors into masks to monitor breathing, t-shirts to monitor heart activity, various home textiles to monitor gases such as ammonia, and breathing to monitor mixing The composition of ammonia was used to monitor people’s liver and kidney function. It is understood that the purpose of developing the ammonia sensor is to test whether the gas sensor can also be well integrated with textiles.

Fahad added: “We have demonstrated applications in monitoring cardiac activity, respiration and sensing gases. Potential future applications include disease diagnosis, monitoring and treatment, as well as batteries, heaters and antistatics. clothing.” So far, the research has been published in Materials Today.

2. How to make wearable sensors more perfect? Need a suitable wire

Wearable sensors are not uncommon these days. If you look up, you may see that a colleague in the office is wearing a smartwatch on the wrist. These hardware sensors are continuously monitoring the health of the body in a non-invasive way. and various situations.

Even if their penetration rate has reached today’s level, there is still a “hard flaw” in the sensors on such wearable devices, that is, a suitable conductive thread has not yet been found, which is also seamlessly integrated into clothes. The reason why wearable sensors are not yet widely available in the market.

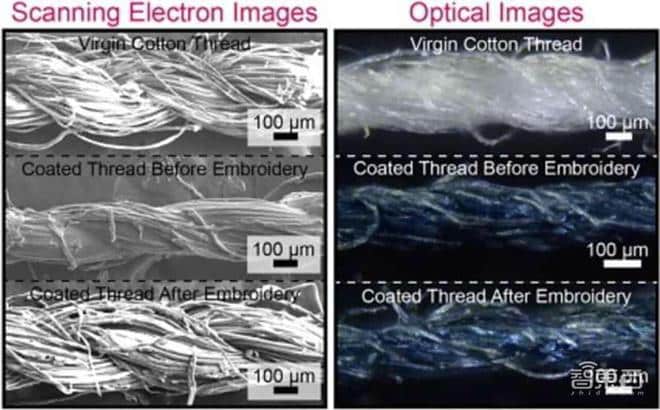

In order to compare with the silver-based conductive thread currently on the market, the researchers compared the sensor with the silver-based conductive thread sensor when and after it was woven into clothing.

▲ Comparison of PECOTEX and silver baseline

During the weaving process, the researchers found that PECOTEX is more reliable and less prone to breakage. This property allows PECOTEX to weave many layers, allowing researchers to develop more complex sensor types. After weaving, the resistance of PECOTEX is lower than that of the silver baseline, that is, PECOTEX is better at conducting electricity. In addition to this, PECOTEX is also machine washable at 30°C.

Dr. Firat Güder, the lead author of the PECOTEX paper, is an associate professor in the Department of Bioengineering, Imperial College London, and previously worked in the group of Professor George M. Whitesides, Department of Biochemistry, Harvard University. He said: “PECOTEX is a powerful and extended It has good performance and can be adapted to more needs, and it can also be mass-produced at low cost using home and industrial computerized textile machines. Currently, we are looking into adding this wearable sensor to everyday clothing to open up more possibilities. PECOTEX can already be seamlessly woven to monitor respiration, heart rate and gas, and in the future, may also be used to aid in the diagnosis and monitoring of disease treatment.”

Conclusion: The technical development space of flexible sensors is large, and the landing direction is broad

Researchers at Imperial College London will explore energy storage, energy harvesting, and new application areas such as biochemical sensing for personalised medicine, and seek commercialisation partners.

The advantage that PECOTEX currently has is that it has initially solved a major problem faced by the new technology, that is, the problem of production cost. At the beginning of the design, researchers have also made PECOTEX compatible with industry-standard computerized textile machines. At the same time, researchers are also trying to solve the problem of production convenience.

In addition, considering that flexible sensors are more convenient and more comfortable, China has not fallen behind in this area.

Since the research and development of flexible sensors is the result of the cross-collision of textile majors and electronic engineering-related disciplines, China and the UK, which have a long history of textiles, are also making relatively rapid progress in terms of progress. A domestic company, Mianjie Technology, launched its own bodyta fiber sensor in 2014. It has the characteristics of close-fitting textiles, free bending, and washability. At the same time, it can complete ECG, EEG, pressure, The perception, conduction, calculation and control of tension and other signals.

Today, Mianjie Technology’s bodyta fiber sensor technology has been applied by AIoT companies such as Xiaomi in body data smart devices such as ECGs, beds, and ergonomic chairs. In the future, PECOTEX team members may gradually implant their own technology into more products.

GIPHY App Key not set. Please check settings