Its sensitivity is 1,000 times that of real skin, and it can detect touch, temperature, moisture and even microorganisms, helping to promote the development of sensitive robots and smart prosthetics. The research was recently published in the journal Advanced Materials Technology.

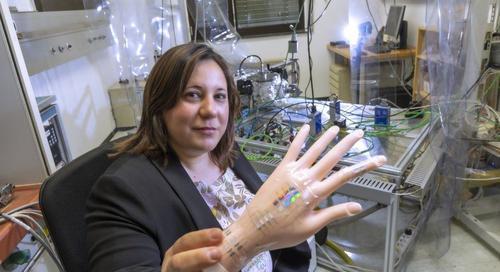

The latest research leader, Italian scientist Ana Maria Cocklett, led a team at the Institute of Solid State Physics at Graz University of Technology in Austria. The smart skin has 2,000 independent sensors per square millimeter, which is more sensitive than human fingertips. Inside each sensor is a smart polymer in the form of a hydrogel, and the outer shell is piezoelectric zinc oxide.

“The hydrogel can absorb water and expand when there are changes in humidity and temperature,” explains Cocklett. During this process, the hydrogel exerts pressure on the piezoelectric zinc oxide, which responds to this pressure and via an electrical signal. All other mechanical stresses. This ultra-thin material can simultaneously respond to force, moisture and temperature with extremely high spatial resolution and emit corresponding electronic signals. This material with multi-sensor properties is the field of intelligent artificial materials technology. ‘Holy Grail’.”

It is reported that the thickness of the first artificial skin samples is 6 microns, while the thickness of human epidermis is 0.03-2 mm. Artificial skin can also be made thinner. In addition, human skin can sense objects about 1 square millimeter in size, and artificial intelligent skin is 1,000 times more sensitive than human skin and can detect smaller objects such as microorganisms.

The researchers say that for the first time, they have developed this smart skin by combining three physicochemical methods: chemical vapor deposition of hydrogel materials, atomic layer deposition of zinc oxide, and nanoprinting lithography of polymer templates. Smart skin is expected to be used in many fields. For example, in the field of healthcare, it can independently detect microorganisms and give relevant reports. It can also be used in human prosthetics that can sense temperature or humidity, and robots that can sense the environment more sensitively.

The core components of the smart skin are produced using a steam-based manufacturing process that is well established so the smart skin can be easily scaled. The research team is currently optimizing the properties of the skin, hoping to expand the temperature range over which the material reacts and increase its flexibility.

GIPHY App Key not set. Please check settings