Due to its tiny body, micro-robots with climbing ability can replace humans to perform special tasks in complex and unstructured environments, and have great application value in detection and biomedicine. Muscle-like soft actuators composed of soft materials can provide robots with excellent flexibility, adaptability and mechanical robustness, and the corresponding microsoft climbing robots have also received extensive attention from researchers. However, there are still huge challenges in how to realize the microsoft climbing robot to climb on various surfaces, and even transition between two different surfaces.

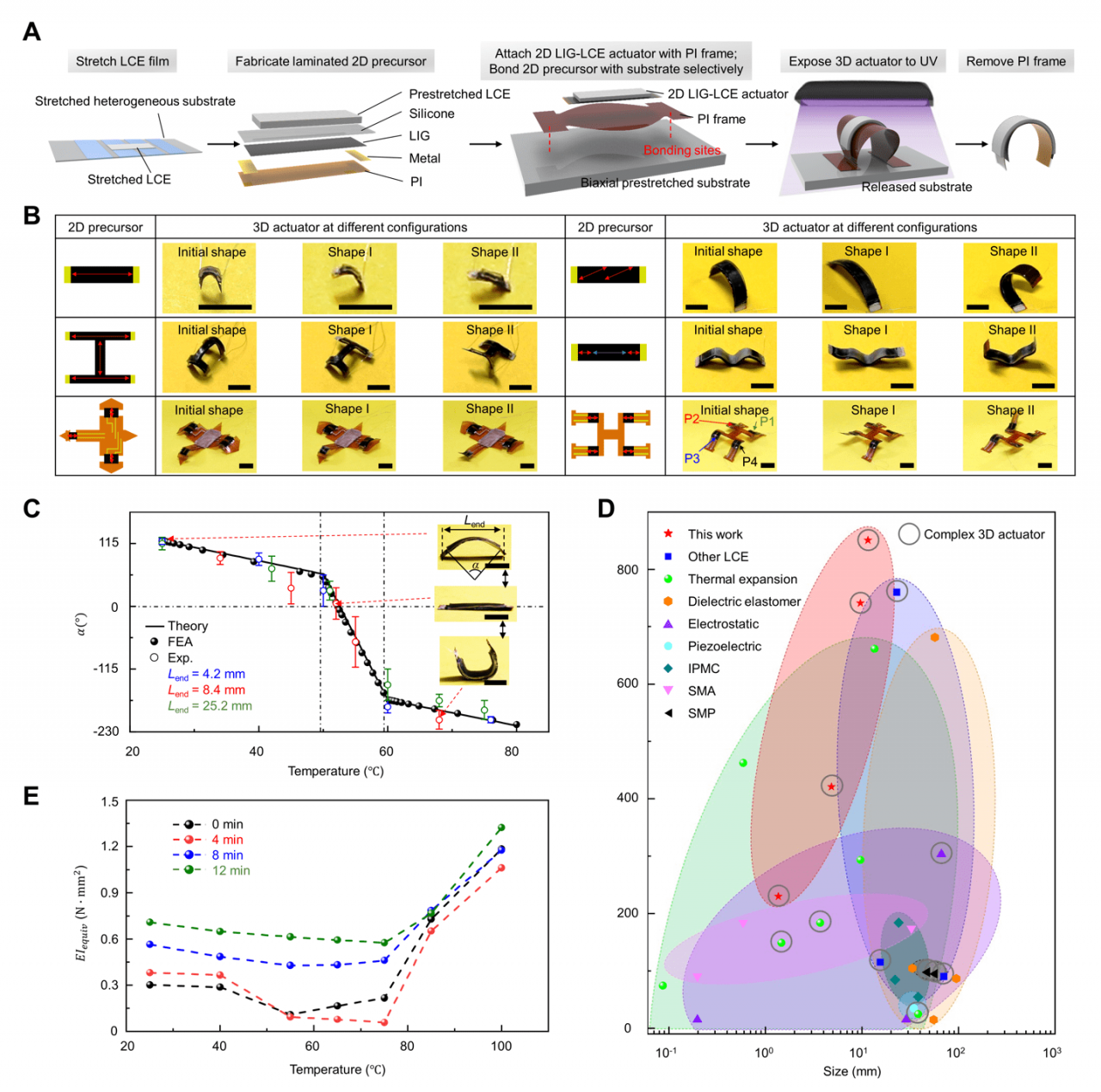

In this study, based on the customized actuation strain design strategy and buckling assembly method of liquid crystal elastomers, the research group developed a series of small-scale electrothermal actuators with customizable three-dimensional deformation capabilities, which have rich three-dimensional configurations and diverse actuation Shapeshifting ability. Compared with existing electrically driven 3D actuators (limited to non-liquid working environments), this type of actuator can achieve complex deformation effects and maximum bending deformation angles at the millimeter scale (from 1 mm to 10 mm). In addition, the actuator has the characteristics of shape recovery and tunable stiffness under temperature (Fig. 1).

Figure 1. Fabrication method and performance characterization of microsoft actuators. Figure A is a schematic diagram of the preparation process of the actuator; Figure B is a three-dimensional actuator with complex deformation effects; Figure C is a representation of the deformation effect of an arc-shaped actuator; Figure D is a comparison of the deformation capability of an existing electric response actuator; Stiffness Change Characterization

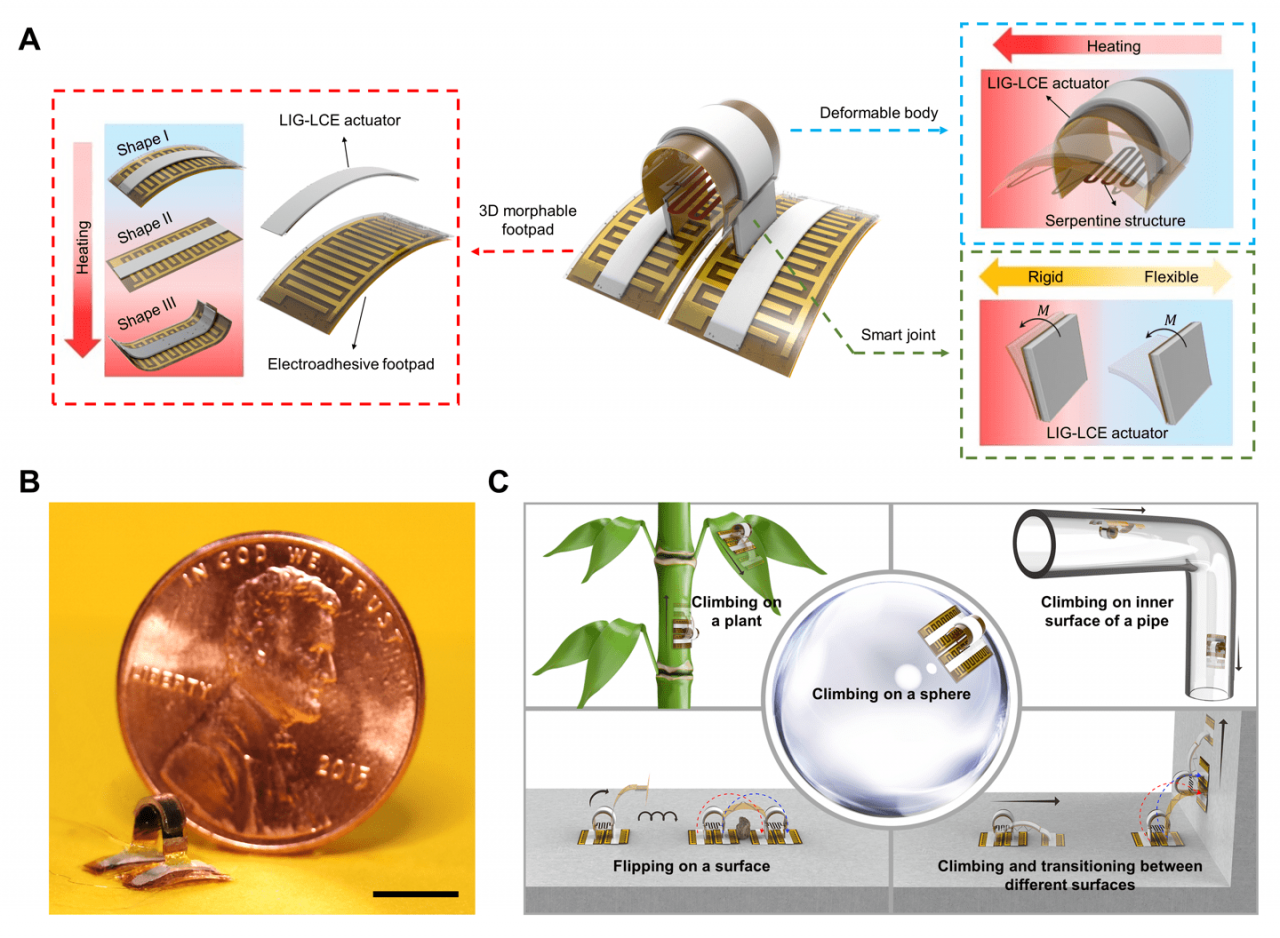

The miniature soft climbing robot prepared based on the above-mentioned customizable three-dimensional drive includes three parts: reconfigurable electrostatic adsorption feet, deformable body and intelligent joints. Through the characterization and analysis of the deformation performance of the robot and the adsorption performance of the foot, the climbing of the robot on surfaces with different shapes, such as the inside and outside of the cylinder, wave surface, wedge surface and spherical surface, can be realized. Inspired by the multiple motion gaits of the plankton Hydra, the robot can switch on demand among three motion gaits of stepping, “somersaulting” forward and flip transition through the control of variable stiffness “smart joints” . Eventually, the robot can climb walls of different materials, different roughnesses, and different shapes, and transition between two different walls (Figure 2).

Figure 2. Design and demonstration of locomotor capabilities of the tiny soft climbing robot. Picture A is a separate view of the various components of the robot; Picture B is an optical image of a robot with a body length of 6 mm; Picture C is a display of the robot’s ability to climb walls of different materials and shapes and transition between walls

Zhang Yihui introduced that after “unlocking” this new skill, the micro soft climbing robot can enter some narrow and complex environments and perform tasks such as detection instead of humans. For example, in complex systems such as aircraft engines and oil refineries, the robot can go through various curved surface structures such as pipelines and gears, and reach the designated position for fault detection and other tasks.

GIPHY App Key not set. Please check settings